Label printing is a very important part of any marketing conversation. The final use of the label to be used, needs to be discussed to see what is possible and will fit into the marketing budget.

There are many options, and some good examples are as follows. If you are looking to simply produce a pallet label, then this really needs to be a basic design, with simple clear to read information on it. Relatively inexpensive and easy to do.

If you were looking to produce a wine label for example, this needs to be what we call in the label industry as a “Shelf Jumper”. A Shelf Jumper, is something that stands out from other on a shelf in a shop. It catches the customers attention over other similar products. With regard to a wine label, this could be the use of a metal foil, an embossing effect or a special varnish. There are many options available.

To achieve this, various finishing techniques are used in label printing, which can enhance the look and feel of the label and create a unique design that stands out on the shelf.

Below, we will explore the various finishing options that are available in label printing, including metal foil, embellishing techniques, laminates, and varnishes, and discuss the uses of these techniques in creating labels.

Metal Foil

Metal foil is a popular finishing option in label printing that is used to create a metallic look on the label. This technique involves applying a thin layer of metal foil, typically gold or silver, onto the label surface using a hot stamping or cold foiling process. The result is a shiny, reflective surface that catches the light and adds a touch of luxury to the label.

One of the primary uses of metal foil in label printing is to create a premium look for high-end products such as cosmetics, alcohol, and gourmet food. For example, a gold foil label on a bottle of champagne can convey a sense of sophistication and elegance, while a silver foil label on a jar of gourmet chocolate can communicate luxury and indulgence. Additionally, metal foil can also be used to highlight specific design elements on the label, such as logos, text, or graphics, making them stand out and catch the eye of the consumer.

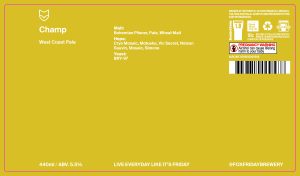

An additional way to create a “Foil” look, is to produce your label on a silver pp which is a shiny metallic label stock, and then to print opaque white where you do not want the foil look.

When the CMYK prints over the top of the label, where it hits the silver pp, it gives a metallic foil look, and then, where the ink prints over the white, it does not. Ink is transparent which means that anything underneath the ink will show through. In this case, the silver shows through where there is no white, and where there is white, it doesn’t allow the silver to come through.

In the example below, in the first image of the design file it looks like there is only a solid gold colour over the whole label. Whereas, in the second image, you can see where the gold colour has no white behind it and the silver stock shines through the gold ink to give it a metallic gold look. This needs to be factored into the design, so always good to chat to use about the intended finish and we can make sure it’s all set up to get the finish you’re after in the most cost effective way.

Embellishing Techniques

Embellishing techniques are another popular finishing option in label printing that can add texture, dimension, and visual interest to the label. These techniques include embossing, debossing, and letterpress, which are used to create raised or recessed areas on the label surface.

Embossing involves creating a raised design on the label surface by pressing the paper or substrate from the back side. This technique can create a tactile, three-dimensional effect that adds depth and dimension to the label. Debossing, on the other hand, creates a depressed design on the label surface, which can create a subtle, elegant effect that adds sophistication and texture to the label. Letterpress involves pressing ink onto the label surface using a raised printing plate, which can create a crisp, textured effect that adds character and personality to the label. See embossing example below.

Please note: Only paper stocks can be used for these effects, as polypropylene and synthetic stocks do not allow the embellishing to cut into them well enough to create this effect.

Laminates

Laminates are a finishing option in label printing that involve applying a thin layer of film onto the label surface to protect it from moisture, abrasion, and fading. There are several types of laminates available, including gloss, matte, and soft-touch finishes.

Gloss laminates create a shiny, reflective surface that can enhance the colour and vibrancy of the label design. This finish is often used in label printing for products that require a high degree of visual appeal, such as consumer electronics, cosmetics, and food packaging.

Matte laminates, on the other hand, create a non-reflective, velvety surface that can add a sophisticated, understated effect to the label. This finish is often used for products that require a subtle, elegant look, such as wine labels or luxury cosmetics.

Soft-touch laminates create a smooth, tactile surface that has a unique, velvety feel.

Rough Touch laminate gives a label a sandy tactile feel which is also very unique.